Precision Grinding Services

B & R Grinding, Inc. is a key provider of high-performance grinding services for applications where tolerances and surface finishes are critical. Our well-equipped facility houses some of the most sophisticated grinding machinery available to industry today. We have a very talented workforce with the mastery to accomplish the most challenging grinding tasks with a superior level of skill and precision. As one of the nation's leading innovators in the field of precision thread grinding, we continually develop improved methods to better serve our customers. We are also a leading practitioner of high-helix thread grinding for ball screws, lead screws, cutting tools and other applications.

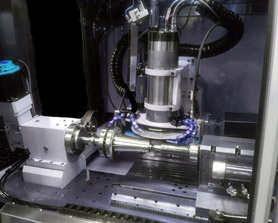

Our services incorporate all grinding processes associated with precision threaded components. In addition to high-end CNC controlled thread grinders, we have equipment specifically built for OD grinding as well as a CNC turning center with multi-tasking capability. Features such as programmable operation, high-speed controls, and position feedback allow us to achieve an exceptional degree of accuracy at very favorable throughput rates.

We have a strong background working with all types of standard and high-strength metals such as titanium and beryllium and other hard materials in the range of 62 RC. Our grinding expertise also applies to plastics and we have the capacity to handle workpieces measuring up to 13" in diameter. We have a large library of dressing tools to accommodate the most complex shapes and profiles. Inspection instruments from the finest manufacturers of metrology equipment allow us to thoroughly examine workpieces for quality and ensure precise dimensional integrity. We also provide engineering and inspection reports as needed.

We have a great deal of experience fulfilling the manufacturing and repair needs of mold makers, tool and die, professionals, machine builders, and gear manufacturers. Our 7,500+ sq ft plant is equipped to manage projects of any size and has both ground level and submerged docks to make deliveries convenient.

With organizational leadership with deep roots in the machining industry, we understand the importance of taking a hands-on approach to machining, inspection, and customer service. We pay attention to every detail to ensure the successful, on-time completion of your project. Contact us today to learn more about our grinding services.

CNC Cylindrical Grinding Machine

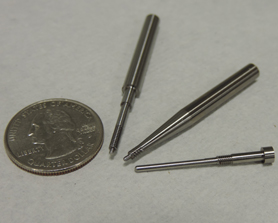

Precision Threaded Components

Angle Grinding

Precision Grinding Capabilities

- Services

-

- CNC Cylindrical Thread Grinding

Worm Grinding

CNC OD Grinding

High Helix Grinding

Turning - Hard Turning

Milling

ID Thread Turning

Engineering & Reverse Engineering Services

- CNC Cylindrical Thread Grinding

- Grinding Process

-

- Angle Grinding

Contour Grinding

External & Outside Diameter

Fine Grinding

Flat Grinding

High-Speed Grinding

Internal and Inside Diameter

Multiple Diameters in One Plunge

Outside Diameter - Precision Grinding

Radii Grinding

Thread and OD Regrinding

Tap Sharpening

Taper Grinding

Wet Grinding

Electrode Grinding

Collapsible Core Grinding

- Angle Grinding

- Machine Capabilities

-

- 5-Drake CNC Thread Grinders

2 - 6" X 36" Rear Dress

1 - 6" X 36" Front Dress

1 - 12" X 45" Rear Dress

1 - LM-200 1 Meter Length - Mitsubishi PD 32 CNC OD Grinders

2 - 40" Length Capability

1 - 20" Length Capability

Mazak Quick Turn

1 – NEXUS 250-II-MY

- 5-Drake CNC Thread Grinders

- Molding Cores

-

- Bubbler

Rotating

Collapsible

Electrodes for EDM - Ballscrews

Worm Gears

Buttress Form

- Bubbler

- Material

-

- Aluminum

Beryllium

Brass

Bronze

Cast Iron

Cobalt

Copper

Hastelloy - Inconel

Nickel

Plastics

Stainless Steel

Steel

Titanium

- Aluminum

- OD Grinding Capabilities

- Max Diameter: 13"

Max Length: 42"

5" Wheel Width Capability

- Thread Grinding Capabilities

-

- Max Diameter: 13"

Max Length: 1-meter Thread Length 45" between centers - High Helix Grinding 180 Degree

Rotary Diamond Roll DressersVoss Thread Styles

- Max Diameter: 13"

- Turning Capabilities

- Max Diameter: 8"

Max Length: 20"

- Quality Control Inspections

-

- Super Micrometers

Starret Super Micrometers

Pratt & Whitney Super Micrometers

Coordinate Measuring Machines

1 - Mitutoyo 700 Series CMM with

Scanning Head - Comparators

1 - Micro Vu 30" Comparator

1 - Micro Vu 20" Comparator

2 - J & L Comparators

1 - CNC CCP-30 Comparator

- Super Micrometers

- Additional Services

-

- CAD Design

CAM

Engineering - Inspection Reports

Reverse Engineering

- CAD Design

- Production Volume

-

- Specialty Production Shop

Prototype

Low Volume

Small Run - High Volume

Large Run

Long Run

Large Scale Production Volume Run

- Specialty Production Shop

- Lead Times Available

- Quoted on Job By Job Basis

Emergency Services Available

Rush Services Available

Additional Information

- Industry Focus

-

- Aerospace

Agricultural

Auto/Truck/Transportation

Machine Tool

Marine - Medical

Military

Mining

Oil and Gas

- Aerospace

- Intended Application

-

- Gearing

Machinery - Mold Building

Tooling/Fixtures

- Gearing

Print This Page

Print This Page